4 Degrees of Freedom Robot Arm With a Twist

4 Degrees of Freedom Robot Arm With a Twist

STM32F4 - Processor in the Loop

- Inverse Kinematics of a Two-Link Planar Elbow Manipulator (Symbolic Math)

- Solving the 4 Degree of Freedom (Matlab Script)

- Simulink Matlab Function Block Implementation

- Simulation with Simscape Multibody

- Processor in the loop with STM32F4 Discovery Board

- What we need

- Results

- Next Steps

This is a documentation of steps being

done to be able to solve the 6 Degree of Freedom Robot Arm bought online. This goes through the process of solving

the inverse kinematics of a Two-Link Planar Elbow Manipulator which is the

basis of our case.

Wrist and Clamps was not solve here &_&

Wrist and Clamps was not solve here &_&

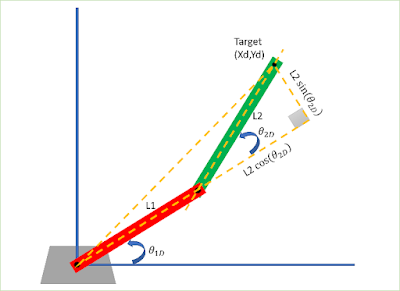

Inverse Kinematics of a Two-Link Planar Elbow Manipulator

q1d, q2d = angles of the links (counter-clockwise

is positive)

th2d :=

Symbol::subScript(Symbol("theta"),"2d"):

th3d :=

Symbol::subScript(Symbol("theta"),"3d"):

th4d :=

Symbol::subScript(Symbol("theta"),"4d"):

L1 := Symbol::subScript(Symbol("rho"),1):

L2 := Symbol::subScript(Symbol("rho"),2):

th1d, th2d, th3d, th4d, L1, L2;

eq6 := op(solve(eq5,cos(th2d)),1);

Solving from the top:

newth1des =

th1des+th2des;

Solving the 4 Degree of freedom:

This is to check that the solution that we have from the

Symbolic Math Toolbox is correct or not

%% Define

the Target Location

%% Top

view angle : th0 (base angle)

%solve for

the angle

% This is

just for Visualization, you only need to get the th1des and

%

translate to solve from the top

newxl2 =

l2*cosd(newth1des);

newxl3 =

l3*cosd(newth2des);

subplot(1,2,1)

subplot(1,2,2)

This is for a fixed 45 Degree angle at the bicep

th2d := Symbol::subScript(Symbol("theta"),"2d"):

th3d := Symbol::subScript(Symbol("theta"),"3d"):

th4d := Symbol::subScript(Symbol("theta"),"4d"):

L1 := Symbol::subScript(Symbol("rho"),1):

L2 := Symbol::subScript(Symbol("rho"),2):

th1d, th2d, th3d, th4d, L1, L2;

eq6 := op(solve(eq5,cos(th2d)),1);

Solving from the top:

newth1des =

th1des+th2des;

newth2des =

th1des;

Solving the 4 Degree of freedom:

This is to check that the solution that we have from the

Symbolic Math Toolbox is correct or not

%% Solving

for a 4 Degree of Freedom Robot ARM

% this is

just an example of solving 4 DoF Robot ARM via making one link

%

(Stationary) from 0 to 360

%% Define

the Target Location

xt = 0.5;

yt = 0.5;

zt = 0.5;

%% Define

your robot arm body parameters

l1 = 1;

l2 = 1;

l3 = 1;

h0 = 0;

%% Top

view angle : th0 (base angle)

% solve

for th0

th0 =

atand(yt/xt);

if th0 < 0

th0 = th0+180;

elseif isnan(th0)

th0 = 90;

end

display(th0)

%% For

loop for Visualization

% we need

to imagine that we have moved into a different Dimention hence

% you can

si that we have change the angle to line lenghts to ut and wt

wt = sqrt(xt^2 +

yt^2);

% Find the

distance from the base of the bicep to the target

dist2target =

sqrt(wt^2 + (zt-h0)^2);

ut =

sqrt(dist2target^2 - wt^2);

%solve for

the angle

angle =

atand(ut/wt);

for counter = 0:360

th1 = counter;

xb =

l1*cosd(th1);

yb =

l1*sind(th1);

% solve

the th1des and th2des with the ik_doublelink that we have solved

% earlier

from our MuPad

[th1des, th2des]

= ik_doublelink_mathworks(wt-xb,ut-yb,l2,l3);

% This is

just for Visualization, you only need to get the th1des and

% th2des

(Solving X and Y)

xl2 =

l2*cosd(th1des);

yl2 =

l2*sind(th1des);

xl3 =

l3*cosd(th1des+th2des);

yl3 =

l3*sind(th1des+th2des);

%display

the x,y and r value

display([wt ut

dist2target])

display([th1

th1des th2des])

%

translate to solve from the top

%

basically we made a PARALLELOGRAM from the solution with th1des and th2des

% and the

angle origin 0 is on the +X axis

newth1des =

th1des+th2des;

newth2des =

th1des;

newxl2 =

l2*cosd(newth1des);

newyl2 =

l2*sind(newth1des);

newxl3 =

l3*cosd(newth2des);

newyl3 =

l3*sind(newth2des);

subplot(1,2,1)

plot(wt,ut,'rx')

xlim([-1 2]);

ylim([-1 2]);

hold on

plot([0,xb],[0,yb])

plot([xb,xb+xl2],[yb,yb+yl2])

plot([xb+xl2,xb+xl2+xl3],[yb+yl2,yb+yl2+yl3])

subplot(1,2,2)

plot(wt,ut,'rx')

xlim([-1 2]);

ylim([-1 2]);

hold on

plot([0,xb],[0,yb])

plot([xb,xb+newxl2],[yb,yb+newyl2])

plot([xb+newxl2,xb+newxl2+newxl3],[yb+newyl2,yb+newyl2+newyl3])

pause(0.1)

end

This is for a fixed 45 Degree angle at the bicep

This is for a fixed 0-360 Degree angle at the bicep

Simulink Matlab Function Block Implementation:

function

[tAngle,bAngle,fAngle,wAngle] = IK(xt,yt,zt)

%#codegen

persistent th0 th1 th2 th3

%

Initialize joint angles on the first pass

if isempty(th0)

th0 = 0;

th1 = 60;

th2 = 0;

th3 = 0;

end

l1 = 1;

l2 = 1;

l3 = 1;

h0 = 0;

% solve

for th0

th0 = 90 -

atand(xt/yt);

if isnan(th0)

th0 = 90;

end

wt = sqrt(xt^2 +

yt^2);

% Find the

distance from the base of the bicep to the target

dist2target =

sqrt(wt^2 + (zt-h0)^2);

ut =

sqrt(dist2target^2 - wt^2);

%solve for

the angle

%angle =

atand(ut/wt);

xb =

l1*cosd(th1);

yb =

l1*sind(th1);

[th1des, th2des]

= ik_doublelink_mathworks(wt-xb,ut-yb,l2,l3);

% translate

to solve from the top

%

basically we made a PARALLELOGRAM from the solution with th1des and th2des

% and the

angle origin 0 is on the +X axis

th2 =

th1des+th2des;

th3 = th1des;

tAngle = th0;

bAngle = th1;

fAngle = th2;

wAngle = th3;

end

function [th1des,th2des]

= ik_doublelink_mathworks(xd,yd,l1,l2)

if sqrt(xd^2 +

yd^2) < l1+l2

% Calculate the forearm link angle

c2 = (xd.^2 + yd.^2 - l1^2 -

l2^2)/(2*l1*l2);

s2 = sqrt(1 - c2.^2);

th2des = atan2(s2, c2);

else % protect

for relative floating point accuracy at th2 = 0

c2 = 1;

s2 = 0;

th2des = 0;

end

%

Calculate the bicep link angle

k1 = l1 + l2*c2;

k2 = l2*s2;

% Mantain

the sign of th1 positive

if xd < 0

&& yd < 0 % if point is in the third quadrant add 2*pi

th1des = 2*pi + atan2(yd, xd) - atan2(k2,

k1);

else

th1des = atan2(yd, xd) - atan2(k2, k1);

end

th1des =

rad2deg(th1des);

th2des =

rad2deg(th2des);

end

Simulation with Simscape Multi Body

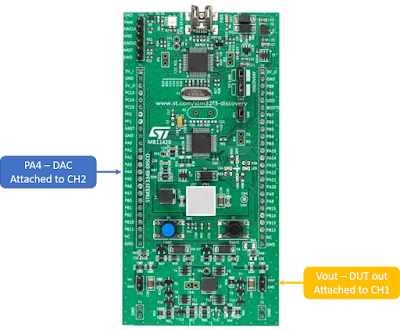

Processor in the loop with STM32F4 Board

What we need:

- STM32F4Discovery Board

- USART Serial Converter (FTDI Basic)

- Two jumper wires for TX and RX

- STM32-Mat Support Package for Matlab/Simulink

- Matlab/Simulink License

- Matlab

- Simulink

- Matlab Coder

- Simulink Coder

- Embedded Coder

Results:

There is no difference between the simulation model and the

code being generated and deployed to the STM32f4Discovery Board (Check Scope 2

Output)

The function IK is being called every 0.001 secs

(fundamental timestep), according to the Code Execution profile of the IK

function, the Maximum Execution time is around 339905 which we need to multiply

by 1e-09 (Default time setting for the measurement) hence the IK Algorithm to

solve the 4 DoF angles would take about 339.91 micro seconds hence calling the function

every 1 milli

seconds is enough to finish the

function in solving the IK of the 4 DoF link arm.

Next Steps:

- Conversion of the Degrees to Servo Motor Control Signal

- Need to add in a 3.3v to 5.0v converter since the STM32Discovery Boards are operating at 3.3 volts

Credits to Mathworks and my Techsource AEG

Comments

Post a Comment